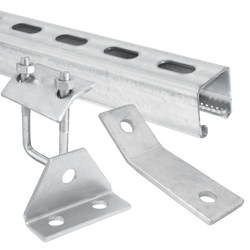

The STRUT type assembly elements make an entire system designed for suspending and mounting various types of ventilation, installation and construction elements.

The main component of the system are the LDB assembly profiles of the Strut type provided with all kinds of L-shaped, trapezoidal and rectangular connectors – fixed and movable.

The important elements also include the ST-ROOF type roof feet which are designed specifically to distribute the load of such elements as generators and AHU units over a larger area of the roof.

Such elements as the W-LDB consoles are used for suspending heavy ventilation and air conditioning units to walls.