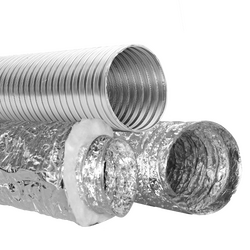

Flexible ducting is a type of ductwork pipe that provides greater flexibility for fitting into narrow, constrained spaces as opposed to rigid spiral or rectangular ducting. Because of its ease of installation, flexibility, and relatively low cost, HVAC contractors choose this system often. Easy to shorten, flexible, and available in 10 m sections, the ductwork is suitable for all types of ventilation or air conditioning systems.

However, flexible ducts have also significant flaws, amongst them, it has low mechanical strengths, meaning the ducting is quite vulnerable to bending and crushing and creates higher airflow resistance.

Flexible ducting can be found not only in industrial ventilation systems, but also in offices, or even in small household vent systems.

For the distribution of hot air from the fireplace, flexible ducting has to handle high-temperature operating conditions. We offer insulated chimney pipes that are heat resistant up to +250oC.

Flexible ductwork with thermal and acoustic insulation is used as a connector to connect the main duct line to the plenum box, due to which they prevent the diffusion of air from losing temperature while also acting as an air silencer.